Rapid Prototyping Tooling

YOUR DESIGN PARTNER

An Essential Part of Modern Manufacturing

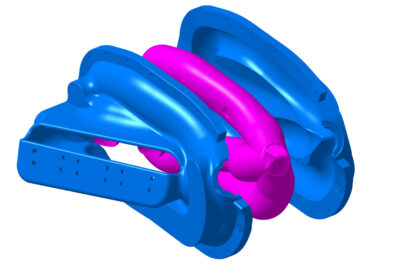

Rapid Prototyping is an essential part of modern manufacturing. Used in part replication, it helps generate samples or simulations that allow greater understanding of the complexities, curvature, general shape and space constraints of a component or alternatively, as production tooling itself. This capability has distinct benefits as it is quickly formed, is a cost-effective solution, especially for small, low volume parts and the entire process, from design concept through to final commodity, is maintained in-house.

As a result, production timeframes and product costs are very controllable and especially so over traditional tooling types such as model board or steel. The other advantages are; parts made using this process reduces design risks, controls material usage, allows visualisation of how a component will appear and if required, permits functionality testing – all on a fast turnaround basis.

Darchem Engineering have two Fused Deposition Modelling (FDM) 3D printing machines located onsite for manufacturing press form tooling, part assembly tooling and demonstration parts. A dedicated design and manufacture team have the ability to rapidly turnaround tooling and parts to the most demanding customer schedules. The machines print from a wide range of materials including ABS, ASA, Polycarbonate and Ultem utilising their strength and thermal properties as required. Machine bed dimensions of 900mm x 600mm x 600mm enable printing of large footprint tooling.

Press

Hammer Form/Fabrication

Compression

Masks

Inspection

Miscellaneous

Our Products

We are a market leader in the design and manufacture (and if required installation) of a wide range of high integrity engineered products in stainless steel and titanium as well as thermal insulation systems for aerospace, motorsport, marine defence, nuclear and oil & gas applications.

Honeycomb Products

A proven track record of design, test, manufacture and installation of metallic honeycomb products for the nuclear, aerospace, automotive and rail markets for over 40 years.

Non-Metallics

A range of non-metallic thermal products including polyimide film encapsulation, soft-blanket insulation, silicone fire barriers and composite heat shields.

Aircraft Component Fabrication

We manufacture complex fabrications in stainless steel and various exotic materials. We can accomodate any size project from single items to high volume batches.

Fire Protection

We are technical experts in offshore and petrochemical passive fire protection systems and all metallic insulation applications for the nuclear sector.

Aircraft Thermal Insulation

Darchem are a leading designer and manufacturer of thermal insulation products to protect key aircraft systems, using high performance materials.