Our Strength is YOUR Advantage

As established thermal management specialists with over 60 year’s product and materials knowledge to a variety of industry sectors and applications, Darchem is an ideal partner to help develop solutions for onerous situations. Using tight tolerance, repeatable, high quality manufacturing methodology, Darchem’s thermal systems are required on a wide variety of applications. Examples being; bends, manifolds, valve and duct thermal protection, through to temperature retention systems to enable engine after-treatment components to work correctly and efficiently.

Whilst dealing with fire and high temperature in confined spaces/hazardous areas can be problematic, the considered approach of a thoroughly capable technical team in reviewing the environment and assessing the most appropriate solution is paramount. Customers appreciate this level of care and attention to detail and this leads in many instances to long-term relationships being formed as the preferred partner of choice.

Why Choose Darchem?

Darchem have over 60 years experience in the Industrial and Process market.

We have a track record of delivering numerus complex projects to a range of customers.

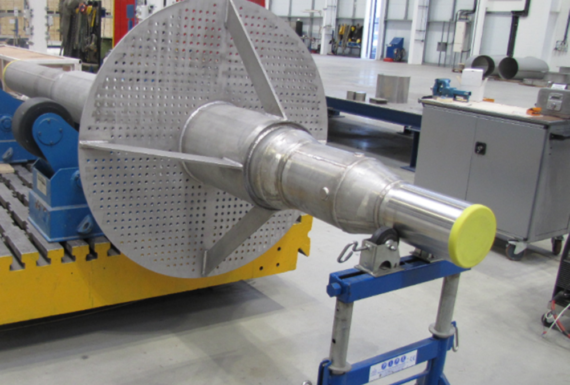

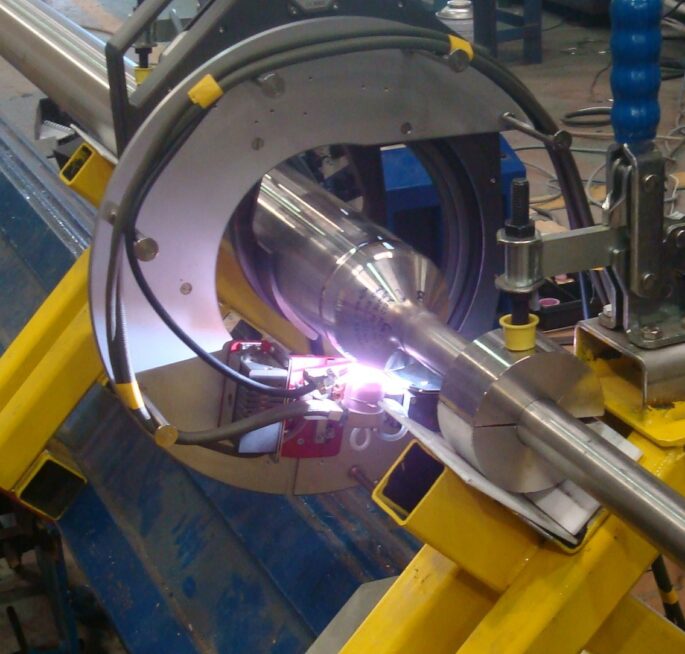

Fabrication and welding of Nickel Alloys and exotic materials are Darchem’s core strengths

Including orbital TIG and state of the art welding processes.